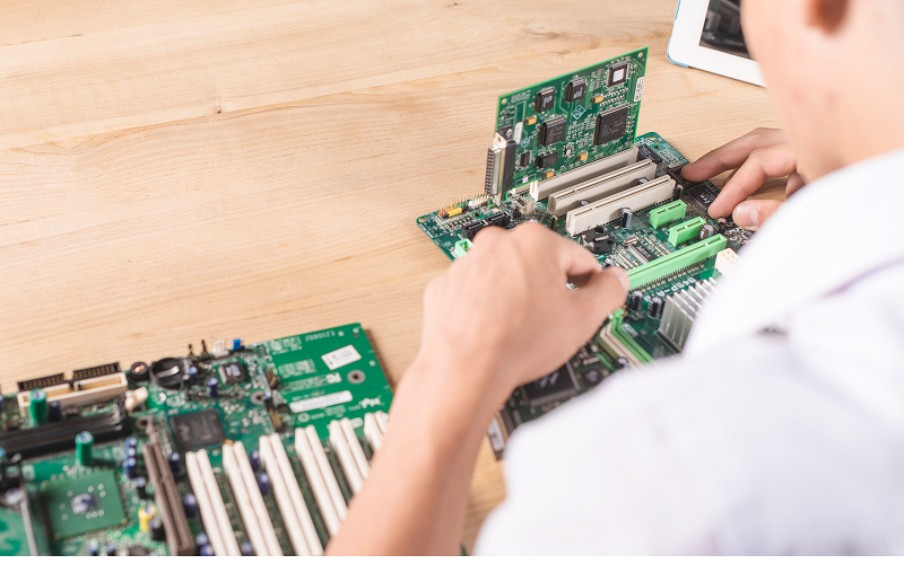

Selecting the right PCB supplier in Singapore is crucial to the success of any electronics project. Whether you are developing prototypes or scaling up for production, the quality, reliability, and support provided by your supplier directly affect performance and timelines. With numerous options available, knowing what to look for in a PCB maker helps you avoid costly delays and technical issues, ensuring your project meets industry standards.

Assess Technical Capabilities and Manufacturing Expertise

A reliable PCB supplier in Singapore should demonstrate strong technical capabilities across different board types and complexities. This includes experience with single-layer, multi-layer, and high-density interconnect boards, as well as the ability to handle varied materials and specifications. An experienced PCB maker understands how design choices affect manufacturability and can provide early feedback to reduce errors during production. This technical input becomes especially valuable for projects with tight tolerances or specialised requirements.

You should also review the supplier’s manufacturing processes and quality control standards. Consistent testing, inspection procedures, and compliance with international certifications indicate a mature operation. Suppliers with in-house fabrication and assembly capabilities often maintain better control over quality and lead times. Companies such as MPN Tech operate with a clear focus on precision and reliability, making them suitable for projects that demand consistent performance.

Evaluate Lead Times, Scalability, and Project Flexibility

Lead time remains a key consideration when selecting a PCB maker. Delays in board delivery can halt production schedules and affect downstream processes. A dependable supplier communicates realistic timelines and adapts to changing project requirements without compromising quality. This level of transparency helps project managers plan more effectively and avoid unexpected disruptions.

Scalability also matters, especially if your project moves from prototyping to mass production. The right PCB supplier in Singapore should support both low-volume and high-volume runs while maintaining consistent standards. Flexible production capacity ensures you do not need to switch suppliers as demand grows, which reduces risk and maintains continuity across project phases.

Review Support Services and Engineering Collaboration

Strong engineering support distinguishes a reliable PCB maker from a basic manufacturer. Suppliers who offer design-for-manufacturing reviews, material recommendations, and troubleshooting support add tangible value to your project. This collaborative approach helps identify potential issues early and improves overall board performance.

Clear communication also plays an essential role. A responsive supplier answers technical queries promptly and provides updates throughout the production process. Working with a PCB supplier in Singapore that prioritises communication allows engineers and procurement teams to resolve issues quickly and keep projects on track without unnecessary escalation.

Check Compliance, Testing, and Industry Standards

Compliance with industry standards ensures your boards perform reliably in real-world conditions. A competent PCB supplier in Singapore adheres to recognised manufacturing and testing standards that align with international requirements. These standards help maintain consistency, safety, and long-term durability across different applications and industries.

Testing processes also reflect a supplier’s commitment to quality. Electrical testing, visual inspection, and controlled handling procedures reduce the risk of defects reaching later production stages. Working with a PCB maker that prioritises compliance and testing helps protect your project from costly failures and reputational risk.

Consider Cost Transparency and Long-Term Value

Cost remains an important factor, but it should not drive decisions in isolation. The lowest quotation does not always reflect the best value, especially if quality issues lead to rework or failures. A reputable PCB maker provides transparent pricing that reflects materials, complexity, and lead times. This clarity allows you to compare suppliers accurately and budget more effectively.

Long-term value often comes from consistency and reliability rather than short-term savings. A trusted PCB supplier in Singapore reduces project risk by delivering boards that meet specifications the first time. Over multiple production cycles, this reliability saves both time and resources, supporting smoother operations and better product outcomes.

Conclusion

Selecting the right PCB supplier in Singapore requires careful evaluation of technical capability, scalability, support, and cost transparency. By engaging an experienced PCB maker that aligns with your project goals, you can enhance quality, reduce delays, and support long-term success. Making informed decisions at the sourcing stage sets a strong foundation for any electronics project.

Work with a dependable PCB maker. Contact MPN Tech for reliable PCB manufacturing and engineering support.